Research & Development Company

DegreeSign is a global research and development company

Our History

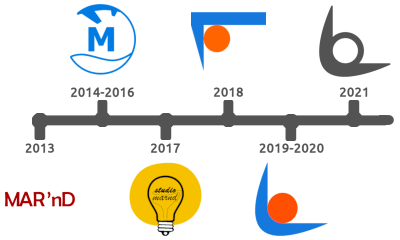

DegreeSign company was founded as MARND in October 2013 to be an aerospace research and development company. The timeline diagram captures our logo evolution over the years.

The company was focused on the development of a practical amphibious passenger vehicle for archipelago inhabitants. It then pivoted in 2016 to the more rapidly developing consumer products market. MARND was incorporated in the United Kingdom in December 2014, as MARND LTD, and its trademark name “MARND” is a registered trademark as of February 2015.

Our Work

Our team has experience in a variety of industries. Aerospace, electric vehicles, consumer electronics, home and industrial tools, wellness & hygiene tools, food & beverages, home & office ware, and more.

2020

Design and manufacturing of a compact disinfectant pump with motion detection to automatically decontaminate surfaces at quarantine access points.

2019

Design and manufacturing of a custom halogenerator for SaltCave with online connectivity to facilitate and streamline commercial management of multiple devices.

2018

Design and manufacturing of eCane for Tasneem, an affordable electronic cane for visually impaired users, allowing them to visualise objects ahead using ultrasound.

2017

Led the manufacturing for Golchi, a dual travel bottle for hot and cold drinks. They had raised USD 400k and were looking to ramp up mass-production.

2016

Research and development of araaq pocketable tool, grouping important personal care items, i.e. a natural toothbrush, mints, and a tiny refillable perfume tube.

2015

Research and development of the next generation Chuester double glass cup using the same beautiful transparency while making it easier to manufacture and use.